Bindery Services

Print finishing or Bindery is a broad term that printers use to describe everything that can be done with or to a printed piece after the printing process is complete. Finishing operations can be basic – like cutting to the finished size from a larger sheet or scoring each sheet to make sure that if folds correctly. Other operations are much more complicated, like multiple folds or die cutting to give the printed piece an unusual shape.

Print finishing or Bindery is a broad term that printers use to describe everything that can be done with or to a printed piece after the printing process is complete. Finishing operations can be basic – like cutting to the finished size from a larger sheet or scoring each sheet to make sure that if folds correctly. Other operations are much more complicated, like multiple folds or die cutting to give the printed piece an unusual shape.

For designers, finishing options provide the opportunity to add some creative zing to your finished product. A special fold, embossing, or foil stamping can add to the value and the appeal of the final design. A combination of fine paper, beautiful art, and a creative die cut can turn an invitation from simple information into a keepsake.

If you’re planning a print project, some sort of finishing will be normally be part of the process. Here are a few tips that you might want to consider:

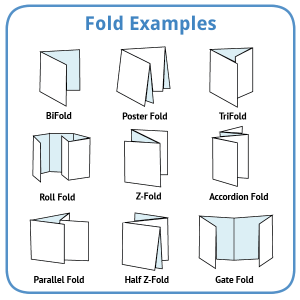

Basic trifold and bifold brochures are a standard format, but they aren’t the only options. Using multiple folds can reveal additional information as the reader explores the printed piece. As an example, a large 11 x 17 sheet can be folded in quarters with information on the outside panels. The inside can be a colorful poster that might wind up on a bulletin board to promote an event.

Basic trifold and bifold brochures are a standard format, but they aren’t the only options. Using multiple folds can reveal additional information as the reader explores the printed piece. As an example, a large 11 x 17 sheet can be folded in quarters with information on the outside panels. The inside can be a colorful poster that might wind up on a bulletin board to promote an event.

When planning for folds, it’s important to think like a reader. Create a folding dummy with a blank sheet of paper and consider what the reader will see as he opens the piece. Create content for the panels of the printed piece that logically flows in the order that it will be opened and read.

Basic folds can usually be done on a machine, but more complex folds may need to be done all or partially by hand. This impacts the cost of the printed piece. Get in touch with Thomas Press for suggestions that can make your folded brochures attractive and cost effective.

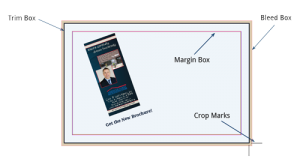

- Size – The standard sheet size for digital printing is 12 x 18. That means that the art, including the bleed area, must be sized to fit the sheet. A standard bleed is ⅛”, so four 5 ½” x 8 ½” postcards will fit on a single sheet. Only two 6” x 9” with bleeds will fit the same sheet. Designing your project to maximize the number of finished pieces on a press sheet will help to minimize the cost.

- Safe area – There is a slight variance that occurs when paper is cut. While you can’t usually see it in a single piece, the image may shift slightly when a stack of paper is trimmed to final size. Allowing an adequate safe area will prevent text from being cut off when the piece is trimmed. ⅛” safe area is recommended, but you probably will want to add more to enhance the readability of the text.

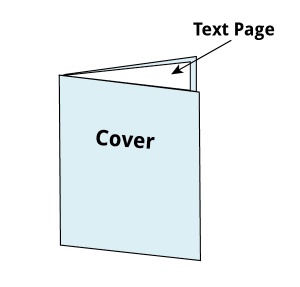

If you’re creating a saddle-stitched (stapled) booklet, it’s important to think about the number of pages. A single sheet of paper folded in half creates 4 pages. This means that booklets will always have a multiple of four pages (4, 8, 12, 16, etc.)

If you’re creating a saddle-stitched (stapled) booklet, it’s important to think about the number of pages. A single sheet of paper folded in half creates 4 pages. This means that booklets will always have a multiple of four pages (4, 8, 12, 16, etc.)

You’ll want to consider the page count and the size of the booklet. Finished size is the folded size of the booklet. A 5 ½” x 8 ½” booklet is folded from an 8 ½” x 11” sheet. Two 8 ½” x 11” sheets will fit on a standard 12” x 18” press sheet, so a 2 sheet/8 page booklet is very economical. Confused yet? Give us a call and we’ll be glad to help.

Lots of Finishing Options

Thomas Press provides a wide variety of bindery and finishing services for our customers and for small printers and print brokers. Here’s are some of the services we offer:

|

|